Often referred to as the "brains" of a renewable energy system, an inverter is an electronic device that converts direct current (DC) power from batteries or solar modules into alternating current (AC) power to operate lights, appliances or anything else that normally operates on electricity supplied by the utility grid. Inverters come in many varieties and sizes, each with different features that are suitable for different

applications.

Grid-Tie Inverters

Grid-tie, or utility intertie, inverters convert DC power from Photovoltaic (PV) modules directly into AC power to be fed into the utility grid. Storage batteries are not needed, as any power produced that's not consumed by the owner's electrical loads is fed into the utility grid to be used elsewhere.

Most battery-less grid-tie inverters are "string" inverters, because the PV modules must be wired together in series to obtain a higher input voltage. String inverters are designed to run at voltages up to 600 VDC, which is the limit imposed by the National Electrical Code (NEC). String wiring is quick and easy to install and the higher voltage helps to minimize line losses and required wire size. However, in string wiring, maximum power point tracking (MPPT), along with any monitoring output, is performed at the string or array level. Central inverters are used in larger commercial grid-tie systems, typically more than 30 kW, as they are usually more economical than using multiple smaller inverters. Due to the high-voltages involved, string inverters should be installed and serviced only by qualified electricians.

Microinverters, such as the Enphase unit pictured here, are typically mounted behind each solar module. They convert the DC output of each module to AC, replacing the high DC voltages (up to 600 VDC) with comparatively lower AC potentials (120 to 240 VAC) and simplifying system design. The microinverter output connects directly to the breakers in the AC load center using conventional wiring. Since microinverters provide MPPT tracking and monitoring for individual modules, the impact of differences in orientation or shading between modules is reduced.

Module optimizers, such as those from Tigo and SolarEdge, mount behind each module like a microinverter and provide individual module MPPT tracking and monitoring, but have a DC output that is connected to a string inverter. These devices simplify system design and increase safety with a smaller financial and efficiency penalty than what is imposed by microinverters.

All grid-tie PV systems use the utility grid for energy storage. Whenever your PV array is generating more power than your loads are using, the excess energy is fed into the grid, literally turning the meter backward. When you need more power than the PV array can supply, the utility makes up the difference. Known as "net metering," this arrangement is the most efficient and cost-effective for grid-tied applications, since there are no batteries to maintain. However, most grid-tie inverters are required by law to shut down during a utility outage. If backup power is required, you will need a dual function grid interactive inverter.

Off Grid Inverters

Off-grid, or battery-based, inverters convert DC electricity from a battery bank to AC. In this case, the PV array and/or wind generator is used to charge the batteries via a charge controller (see our Charge Controllers section for more information) and only the power demanded by the loads is inverted to AC. Because these systems do not have access to the electrical grid, it is important to properly size the inverter and battery bank (see our System Design and Batteries sections for more information on sizing inverters and battery banks).

Off-grid, or battery-based, inverters convert DC electricity from a battery bank to AC. In this case, the PV array and/or wind generator is used to charge the batteries via a charge controller (see our Charge Controllers section for more information) and only the power demanded by the loads is inverted to AC. Because these systems do not have access to the electrical grid, it is important to properly size the inverter and battery bank (see our System Design and Batteries sections for more information on sizing inverters and battery banks).

The nameplate capacity of an inverter is measured by its maximum continuous output in watts. The inverter capacity limits the sum of all AC loads you can operate simultaneously. Most AC appliances list their consumption on a tag located near the power cord and/or in the owner's manual. You will need to add up the consumption of all the appliances you may need to operate at once and that will represent your minimum inverter size. If your appliances include induction motors, like washers, dryers, dishwashers, furnace electronic controls and large power tools, be sure to select an inverter with "surge" capability to accommodate the higher start-up loads.

Off-grid inverters will output either sine wave or modified sine wave (modified square wave) AC waveforms. Sine wave inverters can closely mimic utility grid power and will run virtually any AC appliance. Sine wave inverters with cleaner waveforms, such as the Exeltech XP line, are often desired for sensitive audio or telecommunications equipment. Modified sine wave inverters are an economical choice when waveform is not critical. They often have a high surge capacity for motor starting and generally retain good efficiency when partially loaded. Unfortunately, this type of inverter may damage or fail to operate some sensitive appliances such as rechargeable tools and flashlights, laser printers, copiers, variable speed drives and any equipment with silicon controlled rectifiers (SCRs). Some audio equipment will have a background buzz when operated with a modified sine wave inverter.

Grid Interactive Inverters

Grid interactive, or dual function, inverters can export power to the utility grid, but can also supply emergency backup power for critical loads during a grid outage. These inverters use a battery bank for energy storage (they will not operate without batteries), and include an automatic transfer switch that enables them to safely operate off-grid during a blackout.

The grid interactive inverter is connected to the battery bank (usually 12, 24, or 48 VDC), an AC subpanel for critical loads, and the building's utility entrance load center. The battery bank is charged by the PV array connected through a charge controller (see Charge Controllers). Under normal conditions, it operates like any grid-tie inverter and will export any excess power produced by the PV array. During a grid outage, the inverter will automatically disconnect from the grid, and supply AC power to the critical load subpanel by drawing energy from the battery bank.

When the outage is over, the inverter will automatically switch back to grid-tie operation and recharge the batteries. The Outback Radian GS and the Schneider XW grid interactive inverters have split-phase 120/240 VAC output from a single inverter. The Outback GFX and SMA Sunny Island inverters have 120 VAC output, but two inverters can be "stacked" for 120/240 VAC output.

The SMA Sunny Island is designed to interact with a Sunny Boy grid-tie inverter to create an "AC Coupled" power system. See the Sunny Island listing on page 102 for more information. There is some loss of system efficiency with grid interactive systems, compared to battery-less grid-tie systems.

Output Voltage

Most battery-based inverters in this catalog supply standard 120VAC /60Hz single-phase outputs. The SMA Sunny Island, Magnum MS-4024, and OutBack FX Series inverters can be stacked in pairs for 240VAC. Pairs of OutBack and Sunny Island inverters can also be wired in parallel to provide more output power at 120VAC single-phase, or 120/240VAC split-phase.

The Schneider Xantrex XW and the Magnum MS-PAE inverters deliver 120/240VAC power from one inverter, and can also be wired in parallel for greater power output. Inverters that supply 50 Hz power are also available for most product lines. Contact us with any special requirements that you have.

Interference

Battery-based inverters may interfere with radio and television reception, cause noise on telephones or buzz in audio equipment. Interference can be minimized by using sine wave inverters and by locating the inverter as close to the batteries as practical, twisting together the cables that connect the inverter to the battery, running AC lines separate from other wiring (such as telephone wires) and locating the inverter away from appliances that are susceptible to interference. All inverters cause interference with AM radio reception.

Wiring Considerations

Battery-based inverters require high current from a battery bank to operate large loads. A 2kW inverter will draw nearly 200 A from a 12 VDC battery bank. Large cables and good connections are required for safe operation. Use caution when plugging a small inverter into a lighter outlet in a vehicle, as these outlets are usually not robust enough to handle high current for long periods of time. All battery-based inverters require proper fusing between the battery and the inverter.

Enphase

Grid-Tie Microinverter System

A microinverter converts the DC output from a single PV module into grid-compliant AC power and is meant to be located near the module. The Enphase Microinverter System simplifies design and installation by alleviating string-sizing constraints, and it optimizes the energy harvest of each module through independent maximum power point tracking (MPPT). An Enphase System consists of microinverters, Engage trunk cables (M215) or Installation Kit (M210), the Envoy Communications Gateway, and the web-based Enlighten monitoring and analysis service.

A microinverter converts the DC output from a single PV module into grid-compliant AC power and is meant to be located near the module. The Enphase Microinverter System simplifies design and installation by alleviating string-sizing constraints, and it optimizes the energy harvest of each module through independent maximum power point tracking (MPPT). An Enphase System consists of microinverters, Engage trunk cables (M215) or Installation Kit (M210), the Envoy Communications Gateway, and the web-based Enlighten monitoring and analysis service.

Through individualized MPPT, Enphase microinverters help realize the full energy potential of a PV array, mitigating the effects of shading, dust, debris, module mismatch, and thermal differences. With modulelevel monitoring, performance issues can be traced to individual modules, expediting troubleshooting.

Each PV module is connected directly to its own microinverter mounted on the racking underneath. The microinverter's AC wire harnesses are connected to form an AC branch circuit that leads to the AC utility distribution center. System safety is enhanced since all of the output wiring from the PV array is AC and no high-voltage DC is present once the AC power is shut down, removing that risk for maintenance personnel or firefighters.

Enphase offers two microinverter models, the M215 and the M210, which have different AC wiring methods as described below. All Enphase Microinverters are rated NEMA 6 and operate at full power in ambient temperatures from -40°C (-40°F) to 65°C (149°F), are Listed to UL 1741 for the U.S. and Canada, and comply with IEEE1547, FCC Part 15 Class B CAN/CSA-C22.2 NO. 0-91, .4-04, and 107.1-01. Enphase Microinverters with Canadian content are available by special order.

Enphase M215 Microinverters

The M215 microinverter is compatible with most 60-cell PV modules (up to 260 W) and works with 208 VAC three-phase or 240 VAC single-phase services. The M215 has automatic voltage sensing, but be sure to order the correct trunk cable depending on the type of utility service you're connecting to.

The M215 microinverter is compatible with most 60-cell PV modules (up to 260 W) and works with 208 VAC three-phase or 240 VAC single-phase services. The M215 has automatic voltage sensing, but be sure to order the correct trunk cable depending on the type of utility service you're connecting to.

The maximum number of M215 microinverters in an AC branch circuit is 17 for 240 VAC single-phase systems and 25 for 208 VDC three-phase systems. Each AC branch circuit must be protected with a 20 A circuit breaker. The M215's AC circuit is made using Engage Trunk Cables and accessories.

Be sure to verify that the voltage and current specifications of your PV module match those of the M215 microinverter. For more information, refer to the Enphase website (www.enphase.com/support/downloads) for a list of electrically-compatible PV modules. To ensure mechanical compatibility, be sure to order the microinverter with the correct connector type for the PV module that you are using.

The M215 Microinverters are covered by a 25-year limited warranty.

Enphase Module Level Monitoring

Enphase Energy's monitoring technology is integrated into their microinverters, so there is no need for a separate monitoring system. However, the Envoy Communications Gateway (Envoy) is required to interface with the microinverters and includes access to the Enphase Enlighten online monitoring service. The Envoy plugs into any standard AC outlet and collects microinverter performance information over the existing power line. An Ethernet cable can then be used to connect the Envoy to the installation site's existing Internet access point or local area network. Once online, the Envoy will automatically access the Enphase Enlighten web service.

Enphase Energy's monitoring technology is integrated into their microinverters, so there is no need for a separate monitoring system. However, the Envoy Communications Gateway (Envoy) is required to interface with the microinverters and includes access to the Enphase Enlighten online monitoring service. The Envoy plugs into any standard AC outlet and collects microinverter performance information over the existing power line. An Ethernet cable can then be used to connect the Envoy to the installation site's existing Internet access point or local area network. Once online, the Envoy will automatically access the Enphase Enlighten web service.

The Envoy's LCD display provides at-a-glance performance data, and more detailed per-module information is accessible through the Enphase Enlighten website, which displays each module's real-time performance data in a physically accurate representation of the system. The Enphase Enlighten service can also notify the user or service staff via email when it detects underperforming modules or system faults. One Envoy is required for monitoring on each installation of up to 250 inverters. An Enphase Line Communication Filter (ELCF) is required for installations with more than 250 inverters. The Envoy is Listed to UL 60950.

The Envoy's LCD display provides at-a-glance performance data, and more detailed per-module information is accessible through the Enphase Enlighten website, which displays each module's real-time performance data in a physically accurate representation of the system. The Enphase Enlighten service can also notify the user or service staff via email when it detects underperforming modules or system faults. One Envoy is required for monitoring on each installation of up to 250 inverters. An Enphase Line Communication Filter (ELCF) is required for installations with more than 250 inverters. The Envoy is Listed to UL 60950.

SMA

Sunny Boy Grid-Tie Inverters

The popular SMA Sunny Boy Inverters are available in sizes from 700 W to 10,000 W and can be used in a wide range of applications from small residential systems to very large 3-phase industrial installations. All SMA inverters come standard with built-in LCD digital monitors that display instantaneous power output, the current day's power production, and the total energy produced since installation.

All SMA inverters are Listed to UL 1741, UL 1998 for the U.S. and Canada, and are compliant with IEEE-929, IEEE-1547, and FCC Part 15 A & B and are covered by a standard 10-year warranty, with 5- and 10-year extensions available.

SMA Sunny Boy SB700

The Sunny Boy SB700 has a 120 VAC output and three field-configurable input voltage ranges. The 120 VAC output allows it to be used on 120/240 VAC systems as well as 208 VAC systems.

The Sunny Boy SB700 has a 120 VAC output and three field-configurable input voltage ranges. The 120 VAC output allows it to be used on 120/240 VAC systems as well as 208 VAC systems.

The operating voltage of typical 60-cell grid-tie modules is too low to make strings within the voltage and power input window of this inverter. It can be used with SANYO modules, many thin-film modules, and mono or poly-crystalline modules with 5" cells, such as older 36 or 72-cell PV modules.

The SB700 is housed in a completely sealed NEMA 4 stainless steel enclosure. Outdoor installation is recommended for the sealed inverters so natural air-flow can cool the heat-sink.

SMA Sunny Boy 2000HFUS / 2500HFUS / 3000HFUS

Featuring high efficiency, a slim-line enclosure, and reduced weight, the Sunny Boy HF series inverters can be mounted between wall studs for new construction and space-constrained applications (requires flush-mounting installation frame). Installation is simplified by automatic grid voltage detection and field configuration for positive ground. An input voltage range of 175 VDC to 600 VDC increases module selection and string sizing flexibility. The Sunny Boy HFUS series inverters also feature a modern graphic display, wireless Bluetooth communication, and a built-in DC disconnect switch.

Featuring high efficiency, a slim-line enclosure, and reduced weight, the Sunny Boy HF series inverters can be mounted between wall studs for new construction and space-constrained applications (requires flush-mounting installation frame). Installation is simplified by automatic grid voltage detection and field configuration for positive ground. An input voltage range of 175 VDC to 600 VDC increases module selection and string sizing flexibility. The Sunny Boy HFUS series inverters also feature a modern graphic display, wireless Bluetooth communication, and a built-in DC disconnect switch.

SMA Sunny Boy 3000US, 3800US, and 4000US

The compact Sunny Boy 3000US, 3800US, and 4000US inverters are suitable for residential and light commercial use and include an integrated DC disconnect. They are field configurable for positive ground systems. The 3000US and 4000US are auto-sensing for use on 240 and 208 VAC applications. The 3800US is for 240 VAC only, and is specifically sized for buildings with a 100 A service entrance panel

The compact Sunny Boy 3000US, 3800US, and 4000US inverters are suitable for residential and light commercial use and include an integrated DC disconnect. They are field configurable for positive ground systems. The 3000US and 4000US are auto-sensing for use on 240 and 208 VAC applications. The 3800US is for 240 VAC only, and is specifically sized for buildings with a 100 A service entrance panel

(16 A max AC current). These inverters come with an integrated DC disconnect and fused 4-circuit series string combiner that can be used with fuses up to 20 A, and are shipped with 15 A fuses. Made in the USA.

SMA Sunny Boy 5000US, 6000US, 7000US, and 8000US

The Sunny Boy 5000US, 6000US, and 7000US can be used in 208, 240 and 277 VAC applications. The 8000US can be used in 240 and 277 VAC applications. These inverters also come with a DC disconnect switch that connects to the bottom of the inverter. The disconnect has an integrated fused 4-circuit series string combiner that can be used with fuses up to 20 amps. The disconnect also has an input main lug for array DC input (to be used with a separate combiner box). They are shipped with 15 A fuses. All four models are field-configurable for positive ground systems and made in the USA.

The Sunny Boy 5000US, 6000US, and 7000US can be used in 208, 240 and 277 VAC applications. The 8000US can be used in 240 and 277 VAC applications. These inverters also come with a DC disconnect switch that connects to the bottom of the inverter. The disconnect has an integrated fused 4-circuit series string combiner that can be used with fuses up to 20 amps. The disconnect also has an input main lug for array DC input (to be used with a separate combiner box). They are shipped with 15 A fuses. All four models are field-configurable for positive ground systems and made in the USA.

SMA Sunny Boy 8000TL-US, 9000TL-US, and 10000TL-US

The Sunny Boy TL-US series inverters feature SMA's innovative H5 topology, resulting in efficiencies of up to 98%. The transformerless design reduces weight and cost. The Sunny Boy TL-US inverters are a good choice for commercial 208 VAC three-phase applications of any size. They come with an integrated DC disconnect, but require a separate SMA TLUS Combiner Box with fusing on both the positive and negative DC conductors.

Inverter dimensions (without DC disconnect) are 18.5"W x 24"H x 9"D. Weight of all models is 77 lbs. DC disconnect dimensions are 7'W x 12"H x 7.5"D. Weight of DC disconnect is 8 lbs.

SMA Sunny Boy TL-US Combiner Box

The Sunny Boy TL-US Combiner Box has six positive and six negative fused inputs for up to six module strings and meets the requirement for overcurrent protection on both polarities when using transformerless inverters. Fuses are not included. Use 600 VDC rated KLKD fuses (see Electrical Distribution). The maximum string fuse size is 20 A; however, use the chart below to determine the combined maximum amperage of the array that can be used.

The Sunny Boy TL-US Combiner Box has six positive and six negative fused inputs for up to six module strings and meets the requirement for overcurrent protection on both polarities when using transformerless inverters. Fuses are not included. Use 600 VDC rated KLKD fuses (see Electrical Distribution). The maximum string fuse size is 20 A; however, use the chart below to determine the combined maximum amperage of the array that can be used.

TL-US Combiner Box dimensions are 17.2"W x 12.1"H x 3.8"D. Weight is 8.6 lbs. NEMA 3R enclosure.

SMA Sunny Boy Inverter Data Monitoring and Communications

Accessories

SMA Sunny Beam Bluetooth Wireless Monitor

The Sunny Beam communicates wirelessly via Bluetooth with up to 12 Sunny Boy inverters and graphically displays key performance data. It features fully automatic system monitoring, including an audible alert signal, and is powered by an integrated solar cell and rechargeable battery. The Sunny Beam simultaneously displays power output, daily energy production and total system energy production. It may also be configured to display other parameters, such as the overall CO2 offset or dollar value of electricity produced. A hundred days of system performance data can be recorded, stored, and transferred via a USB interface. Using the included Sunny Beam Webconnect software, data can be transferred to the Sunny Portal website (www.sunnyportal.com) for long-term storage, display, and evaluation. An intuitive set of user menus expedites set-up. The Sunny Beam has a standard range of up to 150' that can be extended using an optional Bluetooth repeater.

The Sunny Beam communicates wirelessly via Bluetooth with up to 12 Sunny Boy inverters and graphically displays key performance data. It features fully automatic system monitoring, including an audible alert signal, and is powered by an integrated solar cell and rechargeable battery. The Sunny Beam simultaneously displays power output, daily energy production and total system energy production. It may also be configured to display other parameters, such as the overall CO2 offset or dollar value of electricity produced. A hundred days of system performance data can be recorded, stored, and transferred via a USB interface. Using the included Sunny Beam Webconnect software, data can be transferred to the Sunny Portal website (www.sunnyportal.com) for long-term storage, display, and evaluation. An intuitive set of user menus expedites set-up. The Sunny Beam has a standard range of up to 150' that can be extended using an optional Bluetooth repeater.

All HFUS inverters are set up to communicate with the Sunny Beam. For all other SMA inverters, order a Bluetooth Piggyback card for each inverter to be monitored. Sunny Beam includes a standard 5-year warranty.

SMA Sunny WebBox – Sunny Portal Connection

The Sunny WebBox provides a connection between the SMA inverters and the free Sunny Portal website (www.sunnyportal.com). The Sunny WebBox stores system performance data in its internal 8 MB memory (12.5 MB with the Bluetooth version) or on a standard SD memory card and can be set to upload the data to the Sunny Portal website at user-selectable intervals. The WebBox can be connected to a Sunny Boy, Sunny Tower, Sunny Island, or Sunny Central inverter, and Sunny SensorBox devices (up to 50 units total). The Sunny WebBox reports faults immediately by e-mail or text message. Measurement data can be transmitted to the Sunny Portal via a GSM modem from remote locations where no DSL or telephone connection is available.

The Sunny WebBox provides a connection between the SMA inverters and the free Sunny Portal website (www.sunnyportal.com). The Sunny WebBox stores system performance data in its internal 8 MB memory (12.5 MB with the Bluetooth version) or on a standard SD memory card and can be set to upload the data to the Sunny Portal website at user-selectable intervals. The WebBox can be connected to a Sunny Boy, Sunny Tower, Sunny Island, or Sunny Central inverter, and Sunny SensorBox devices (up to 50 units total). The Sunny WebBox reports faults immediately by e-mail or text message. Measurement data can be transmitted to the Sunny Portal via a GSM modem from remote locations where no DSL or telephone connection is available.

With the standard Sunny WebBox, connection to the inverter or SensorBox device is made with a 4-conductor twisted pair cable between the inverter's RS-485 output and the WebBox terminals. Each inverter requires an RS-485-N Communication Module.

With the Bluetooth version, wireless communication between the inverter(s) and the Sunny WebBox is automatic with a range of up to 330' which can be extended using one or more Bluetooth Repeaters. Each inverter requires integrated or Piggyback card based Bluetooth output.

Both Sunny WebBox versions connect to a local area network (LAN) with an Ethernet cable or to a phone line with a modem. Both are password protected and are covered by a 5-year warranty.

SMA Sunny SensorBox

The compact Sunny SensorBox installs at the PV array to continuously monitor solar irradiation and module temperature, which can be used to calculate the expected output of the PV array for comparison to the actual power output of the inverters. This can help identify and troubleshoot reductions in energy yield.

The compact Sunny SensorBox installs at the PV array to continuously monitor solar irradiation and module temperature, which can be used to calculate the expected output of the PV array for comparison to the actual power output of the inverters. This can help identify and troubleshoot reductions in energy yield.

The included Power Injector feed-in unit connects to the SensorBox via the RS485 communication bus to provide power to the SensorBox and includes a plug-in power supply (120 VAC required).

The Sunny SensorBox sends data to the Sunny WebBox via an RS-485 data link, or by wireless communication with the addition of the Bluetooth version of the Power Injector (purchased separately). From there, the data can be transferred to a PC for further processing or to the Sunny Portal for automatic performance analysis. The Sunny SensorBox can accommodate up to 3 additional sensors, such as ambient temperature, wind speed and an additional irradiance sensor. The Sunny SensorBox is covered by a 5-year warranty.

SMA Power Measurement Kit

The Power Measurement Kit provides ANSI C12 Revenue Grade metering, which is often required for Production Based Incentive (PBI) markets. This kit is based on the i.LON SmartServer, Shark 100 meter, and three current transformers and includes a fuse kit.

The i.LON SmartServer Modbus Gateway provides a remote network interface into both LonWorks (ANSI 709.1) devices and Modbus devices. The i.LON has been customized for the SMA line of inverters to access controls and monitor the operation of the inverters.

The Shark 100 meter exceeds Ansi C12.20 (0.2%) and IEC 687 (0.2%) energy measurement standards and communicates to the SmartServer over Modbus RTU.

SMA

Sunny Island SI5048-US

The Sunny Island 5048-US is a bi-directional battery-based inverter/charger that can be used completely off-grid, or for battery backup in grid-tie systems with Sunny Boy grid-tie inverters. The Sunny Island is a complete high efficiency power center all in a compact wall-mounted package. It includes 5 kW of sine wave output power, low idle losses, and a 100 A battery charger, and offers an integrated data monitoring system with battery disconnect.

The Sunny Island 5048-US is a bi-directional battery-based inverter/charger that can be used completely off-grid, or for battery backup in grid-tie systems with Sunny Boy grid-tie inverters. The Sunny Island is a complete high efficiency power center all in a compact wall-mounted package. It includes 5 kW of sine wave output power, low idle losses, and a 100 A battery charger, and offers an integrated data monitoring system with battery disconnect.

Grid-Tie System Backup

The Sunny Island can provide back-up power for critical loads during utility grid blackouts. Combined with a Sunny Boy grid-tie inverter system and a bank of batteries, the Sunny Island will enable the PV array to power loads and charge the batteries. As an "AC-Coupled" system, the AC output of Sunny Boy grid-tie inverter is connected to a critical-loads subpanel rather than the main panel. The subpanel

is also connected to the AC output of one or more Sunny Island inverters. Under normal conditions, the power from the PV array and the Sunny Boy inverters passes through the subpanel and the Sunny Island's built-in transfer switch on its way to the grid, without loss of efficiency. Likewise, grid power can pass the other direction when needed. During a power outage, the Sunny Island isolates itself from the grid and provides AC power to the emergency subpanel, drawing energy from the battery bank. The grid-tie Sunny Boy inverter will shut down during a blackout, but will turn back on (after a 5-minute period) when AC power from the Sunny Island is present. AC power from the Sunny Boy inverter(s) can be used by the Sunny Island to charge the batteries. If the batteries are full, and the PV system is producing more power than the loads require, the Sunny Island will communicate with the Sunny Boy inverter to decrease its power output. If there are no loads and the batteries are full, the Sunny Boy inverter will automatically shut off to prevent battery over-charging.

Off-Grid Power

In off-grid systems, the Sunny Island works with Sunny Boy inverters exactly as it does with grid-tie systems during a grid outage. A generator can be connected to the Sunny Island's AC input to provide back-up and battery charging. The battery bank can also be charged using a PV array with a standard PWM or MPPT charge controller, or by other power sources like microhydro and wind turbines.

Data Monitoring

The Sunny Island utilizes removable SD cards to store performance data from the integrated data logger and to perform firmware upgrades. State-of-charge metering helps with battery management to ensure maximum battery life. The Sunny Island works with the SMA Sunny WebBox and SensorBox monitoring accessories.

The Sunny Island SI5048-US is Listed to UL 1741 for the U.S. and Canada and carries a 5-year warranty.

SMA MCB-12U Multi-Cluster Box for the Sunny Island 5048-US

The Multi-Cluster Box for the Sunny Island 5048-US enables easy installation of three-phase hybrid systems. Connect up to four parallel three-phase clusters, each consisting of three Sunny Island battery inverters, for 30 kW, 45 kW, or 60 kW of inverter capacity. The Multi-Cluster Box is pre-wired with 300 A main disconnect breakers for the grid or generator connections, loads, Sunny Boy inverters, plus 70

A AC input breakers for up to 12 Sunny Island battery inverters. The Multi-Cluster Box also includes a load shedding contactor and communication cables.

NEMA 12 enclosure standard: NEMA 4 or 4X available. Size: 65"H x 48"W x 14"D. Weight: 485 lbs. Listed to UL 508A. 5-year warranty.

OutBack

NEW! Radian Grid-Tie or Off-Grid Inverters and Systems

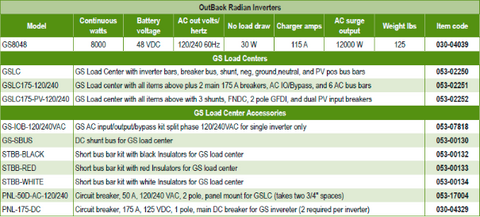

Outback's new Radian inverter works equally well as a grid tie or off-grid inverter. There are two separate AC inputs, one for the bi-directional grid connection and one for a back-up generator. There is a built-in 50 A transfer switch at 120/240 VAC. The output is 120/240 VAC split phase in each unit for easy tie-in to US standard wiring and grid connections. The Radian features 8 kW of continuous output power and can support large dynamic load variations and surge loads, making it well-suited for demanding commercial applications as well as residential use. With two power stages, it is able to provide high efficiency and redundancy for critical applications, and the modular design is field serviceable. The Radian can be parallel stacked with up to 10 inverters for 80 kW total output. The Radian also has auxiliary controls which include a contact closure, a 12 VDC output signal and terminals for a remote on/off switch.

Outback's new Radian inverter works equally well as a grid tie or off-grid inverter. There are two separate AC inputs, one for the bi-directional grid connection and one for a back-up generator. There is a built-in 50 A transfer switch at 120/240 VAC. The output is 120/240 VAC split phase in each unit for easy tie-in to US standard wiring and grid connections. The Radian features 8 kW of continuous output power and can support large dynamic load variations and surge loads, making it well-suited for demanding commercial applications as well as residential use. With two power stages, it is able to provide high efficiency and redundancy for critical applications, and the modular design is field serviceable. The Radian can be parallel stacked with up to 10 inverters for 80 kW total output. The Radian also has auxiliary controls which include a contact closure, a 12 VDC output signal and terminals for a remote on/off switch.

The inverter comes with a standard 5-year warranty. An optional 10-year extended warranty is available where required by state incentive programs. The Radian is for indoor use only. Dimensions are 28"H x 16"W x 8.7"D. Weight is 125lbs. Listed to UL 1741 for U.S. and Canada.

You will also need a Mate 3, Hub 4 or 10, RTS, and an appropriate GSLC (below) to complete a Radian system.

The GS Load Center (GSLC) is a wiring and circuit protection enclosure that mounts under the Radian inverter. It is available in three versions:

The base GSLC includes positive and negative main inverter bus bars, a 500 A 50 mV shunt with negative terminal bar, the main DC positive breaker plate, ground and neutral terminal bars, and 2 PV positive terminal bars. It can also accommodate up to 18 AC or DC panel mount breakers (10 top, 8 bottom), two main 175 A DC breakers and a FlexnetDC, which can be purchased separately. Up to two

charge controls can mount on the right side (mounting brackets not included), and either the Hub4 or Hub10 can mount on the left side.

The GSLC175-120/240 has everything that the basic unit has and also includes two 175 A DC main breakers, an AC output and bypass breakers with interlock plate, an AC grid and generator input breakers (50 A two pole), and six AC terminal bars (3 black, 3 red). It can also accommodate 10 additional panel mount breakers and one additional main breaker, which can be purchased separately. The GSLC175-PV-120/240 has everything that the other versions have and also includes two 80 A PV array breakers, a two pole GFDI 80 A breaker, three 500 A 50mV shunts with shunt bus, and a FlexnetDC. The GFDI acts as the breaker between the control and

positive bus, there are no other breakers added for this purpose. It can also accommodate 5 additional panel mount breakers, which

can be purchased separately.

The AC bypass assembly is only for use with a single Radian inverter. For multiple inverters, use the basic GSLC with added DC and AC breakers as needed (no bypass) and use external transfer switches for bypass and external AC load centers for output combining and input distribution. One GSLC is required for each Radian inverter, and each inverter requires two 175 A main DC breakers.

The GSLC is for indoor use only. Dimensions are 17"H x 16"W x 8.5"D. Weight is 26, 37, or 38 lbs. Listed to UL 1741 for U.S. and Canada.

Magnum Energy

True Sine Wave Inverter/Chargers

MM-Series Sine Wave Inverter/Charger

The MMS Series sine wave inverters provide a cost-effective solution for smaller power needs in mobile applications. The MMS is smaller, lighter and less expensive, while retaining all the built-in protection and reliability of the ME and MS models. The MMS charger has an 85% efficient PFC (power factor corrected) charger. The MMS1012G model comes with a flexible cord on the AC input and a GFCI outlet for easy connection to AC appliances. This mobile inverter is particularly well-suited for mobile or emergency applications; just connect to a 12 VDC battery and you have clean sine wave power anywhere. Optional MMS-RC-25 remote control available. The MMS Series is Listed to UL 458 for the US and Canada, CSA C22.2 #107.1-01 and meets the KKK-A-822E standard. Made in USA.

The MMS Series sine wave inverters provide a cost-effective solution for smaller power needs in mobile applications. The MMS is smaller, lighter and less expensive, while retaining all the built-in protection and reliability of the ME and MS models. The MMS charger has an 85% efficient PFC (power factor corrected) charger. The MMS1012G model comes with a flexible cord on the AC input and a GFCI outlet for easy connection to AC appliances. This mobile inverter is particularly well-suited for mobile or emergency applications; just connect to a 12 VDC battery and you have clean sine wave power anywhere. Optional MMS-RC-25 remote control available. The MMS Series is Listed to UL 458 for the US and Canada, CSA C22.2 #107.1-01 and meets the KKK-A-822E standard. Made in USA.

MS-Series Sine Wave Inverter/Chargers

The MS Series inverter/charger is a sine wave inverter designed for the most demanding mobile and off-grid applications. The powerful, easy to use, MS Series inverters are available in 12, 24, and 48 VDC versions. The MS4024 can be series stacked, using the ME-SSI, for 120/240 VAC operations, and 8 kW total output. The MS2012-20B has two 20 A AC breakers built in. The M4024-PAE and MS4448- PAE

The MS Series inverter/charger is a sine wave inverter designed for the most demanding mobile and off-grid applications. The powerful, easy to use, MS Series inverters are available in 12, 24, and 48 VDC versions. The MS4024 can be series stacked, using the ME-SSI, for 120/240 VAC operations, and 8 kW total output. The MS2012-20B has two 20 A AC breakers built in. The M4024-PAE and MS4448- PAE

have 120/240 VAC split-phase output, and can power 240 VAC loads without stacking. As many as four MS-PAE inverters can be paralleled for larger systems up to 17.6 kW with 120/240 VAC split-phase output (ME-RTR router required).

Mount the MS Series on a shelf or bulkhead, even upside down, or use Magnum's integration hardware (pg 116). The aluminum base and cover provide noise reduction and corrosion resistance. The MS Series has an RS-485 communication port and a remote control port. The front panel has an on/off switch with an LED indicator. All models have a 50 A transfer relay. The ME-RC50, ME-ARC50, or ME-RTR controller is required for inverter programming.

The MS Series is Listed to UL 458 for mobile use and UL 1741 for off-grid installations. Dimensions: 13.75"H x 12.65"W x 8"D. Most units include a 3-year warranty, except MS4024-PAE and MS4448-PAE which have a 2-year warranty. Made in USA.

Magnum Energy Modified-Sine Wave Inverter/Chargers

MM-Series Inverters

The MM-Series 12 VDC inverter/charger is designed for entertainment systems and small appliances in smaller remote homes. The MM is smaller, lighter and less expensive than the ME while retaining all the built-in protection and reliability of ME models. The MM models use an 85% efficient PFC (power-factorcorrected) charger and the same charger topology as all Magnum models. The 600 and 1500 W models have a 12 VDC input; a 1500 W model with a 24 VDC input is also available. The powerful, easy-to-use MM Series are cost-effective and come with a 2-year warranty. Dimensions: 16.6"H x 8.4"W x 4.7"D.

The MM-Series 12 VDC inverter/charger is designed for entertainment systems and small appliances in smaller remote homes. The MM is smaller, lighter and less expensive than the ME while retaining all the built-in protection and reliability of ME models. The MM models use an 85% efficient PFC (power-factorcorrected) charger and the same charger topology as all Magnum models. The 600 and 1500 W models have a 12 VDC input; a 1500 W model with a 24 VDC input is also available. The powerful, easy-to-use MM Series are cost-effective and come with a 2-year warranty. Dimensions: 16.6"H x 8.4"W x 4.7"D.

ME-Series Inverters

Designed for RV use, the ME Series 12 VDC inverter/charger charges batteries efficiently even at low AC voltage from low-cost generators. The modified sine wave inverter keeps the cost down and a battery temperature sensor optimizes charging. ME inverters have 3 power levels and built-in ground switching required for mobile inverters that may connect to utility power. ME inverters are Listed to UL 458 in the US and Canada for RV, marine and mobile use and come with a 3-year warranty. Dimensions: 16.6"H

Designed for RV use, the ME Series 12 VDC inverter/charger charges batteries efficiently even at low AC voltage from low-cost generators. The modified sine wave inverter keeps the cost down and a battery temperature sensor optimizes charging. ME inverters have 3 power levels and built-in ground switching required for mobile inverters that may connect to utility power. ME inverters are Listed to UL 458 in the US and Canada for RV, marine and mobile use and come with a 3-year warranty. Dimensions: 16.6"H

x 8.4"W x 4.7"D.

RD-Series Inverters

The RD Series 12 VDC inverter/charger is designed specifically for off-grid use with the same chassis as the MS sine wave inverters. Includes power-factor-corrected charger, modified sine wave inverter and battery temperature sensor. The RD inverters are Listed to UL 1741 and include a 2-year warranty. Dimensions: 16.6"H x 8.4"W x 4.7"D.

Magnum Energy Accessories and Options

The optional ME-RC50 remote control is simple to use, yet enables use of all the set-up features of the ME, MS, MS-ME, and RD Series inverters. The ME-RC50 controls the ME-AGS automatic generator start using a network connection to the inverter. This remote has convenient fingertip operation, including one-knob programming. The new ME-ARC50 advanced remote offers even more control of the setup including custom battery charge set-points.

The optional ME-RC50 remote control is simple to use, yet enables use of all the set-up features of the ME, MS, MS-ME, and RD Series inverters. The ME-RC50 controls the ME-AGS automatic generator start using a network connection to the inverter. This remote has convenient fingertip operation, including one-knob programming. The new ME-ARC50 advanced remote offers even more control of the setup including custom battery charge set-points.

The optional Auto Generator Start (ME-AGS) module automatically starts and stops most major generator brands. The generator can automatically start based on low battery voltage or on the inside temperature, starting a generator to run an air conditioner when the temperature of an RV or cabin rises to a user defined level.

The ME-AGS-S is the 'standalone' version of Magnum Energy's Automatic Generator Start controllers, and can be used in power systems that don't have a Magnum inverter.

The ME-AGS-N is the 'network' version of Magnum Energy's Automatic Generator Start controllers and is set up and operated via a Magnum Energy Inverter and ME-RC50 or ME-ARC50 remote panel. When using the ME-RC50 Remote, the ME-AGS-N has basic adjustments starting on battery voltage or temperature. When using the ME-ARC50 Remote, the ME-AGS-N has advanced start and stop settings based on: time of day, battery State-of-Charge, battery voltage, high temperature, or inverter load amps. The ME-AGS-N also includes the ability to manually turn the generator on and off, generator exercise, warm-up and cool-down.

The optional ME-SSI allows a series connection of two MS4024 inverters for 120/240 VAC split phase output at 8 kW total power output.

ME-BMK monitors battery percentage state-of-charge (SOC), along with amps, voltage, A hours and min/max DC volts, and then provides this information in an easy-to-understand display via the ME-RC50, ME-ARC50, or ME-RTR remotes. Kit includes a sense module, shunt and wiring. The MM-RC25 provides on/off control and a quick indication of inverter and charger operation.

Magnum Energy MMP Mini Magnum Panel

The MMP - Mini Magnum Panel - is an inclusive, easy-to-install panel designed to work with one Magnum MS-AE, MS, RD or other non-Magnum inverter/charger. The MMP features a small footprint and comes prewired for fast installation. Circuit breakers and the optional remote control mount on the front of the cabinet. Dimensions are 12.5" wide x 18" tall x 8" deep. They are Listed to UL 1741 and CSA C22.2 107-01. Each MMP includes one DC breaker – 175 A or 250 A, one AC bypass breaker – 30 A dual pole or 60 A single pole, one AC input breaker – 30 A dual pole or 60 A single pole, a 500 A/50mV shunt, DIN rail provided for up to eight DC ½" DIN mount breakers (pg 119), or if the DIN rail is removed, four 1" wide surface mount breakers (see Electrical Distribution). Panels are available for inverters with 120 VAC output and 120/240 VAC output.

Magnum Energy MP Magnum Panels

The MP Magnum Panels are available in three sizes, each with either a 30 A two-pole 120/240 VAC output breaker or a 60 A 120 VAC output breaker. They are designed for use with two series-stacked MS4024 inverters, or up to four parallel connected MS-PAE inverters.

The MP Magnum Panels are available in three sizes, each with either a 30 A two-pole 120/240 VAC output breaker or a 60 A 120 VAC output breaker. They are designed for use with two series-stacked MS4024 inverters, or up to four parallel connected MS-PAE inverters.

The MPSL (magnum panel, single enclosure, low capacity) accommodates up to 2 inverters with the use of an MPX Extension Box. It includes a 250 A DC breaker, a 125 A AC bypass breaker, a 500 A/50 mV shunt and inverter AC input protection, and all AC/DC wiring for dual inverters (source/ load wiring not included).

The MPSH (magnum panel, single enclosure, high capacity) accommodates a maximum of 3 inverters. One inverter can be connected directly to the MPSH. Each additional inverter requires an MPX. The MPSH includes one 250 A DC breaker, a 125 A AC bypass breaker, a 1000 A/100 mV shunt and inverter AC input protection, and all AC/DC wiring for dual inverters (source/load wiring not included).

The MPDH (magnum panel, dual enclosure, high capacity) accommodates as many as 4 inverters with 2 enclosures – one for AC and one for DC connections. Two inverters can be connected to the MPDH. The third and fourth inverters require one MPX for each. The MPDH includes two 250 A DC breakers, a 125 A AC bypass breaker, a 1000 A/100 mV shunt and inverter AC input protection, and all AC/DC wiring for dual inverters (source/load wiring not included)

Mount and connect additional inverters to MP Series Systems Panels using MPX Series Extension Boxes. They mate to the bottom of Magnum MS4024 or the MS-PAE inverters. The boxes include a 250 A DC breaker and all AC and DC inverter wiring for adding another inverter. Left and right-hand versions mount on either side of an MP Panel. An MP-HOOD inverter hood (not shown) allows vertical mounting. Choose from six extension box models depending on the type MP enclosure to be installed and which side of the MP enclosure it will be installed on.

Morningstar

SureSine 300 W Inverters

The Morningstar SureSine pure sine wave inverter is designed to meet the needs of rural PV electrification requiring AC power for solar home systems, schools, community centers and health clinics. This inverter is also a good choice for small PV systems for telecom, remote cabins and weekend homes, and RV/caravans and boats. It has outstanding surge capability for a small inverter. The SureSine handles a 200% surge during load start-up, to a maximum of 600 W.

The Morningstar SureSine pure sine wave inverter is designed to meet the needs of rural PV electrification requiring AC power for solar home systems, schools, community centers and health clinics. This inverter is also a good choice for small PV systems for telecom, remote cabins and weekend homes, and RV/caravans and boats. It has outstanding surge capability for a small inverter. The SureSine handles a 200% surge during load start-up, to a maximum of 600 W.

The SureSine uses epoxy encapsulation, conformal coating, stainless steel hardware, and an anodized aluminum enclosure to protect against harsh tropical and marine environments. AC output connection does not have an AC receptacle so it needs to be hardwired. 2-year warranty.

Dimensions are 8.4"H x 6"W x 4.1"D. The 115V inverter is UL Listed for the U.S. and cUL Listed to CSA C22.2 No. 107.1-01 for Canada.